Project Researcher: Miguel Camilleri

Hybrid lenses incorporate multiple optical functions into one single lens. High precision hybrid lenses are currently made from glass. Injection moulding of hybrid lenses would be advantageous due to lower production costs. This possibility was investigated in this research project by designing, manufacturing and measuring hybrid lens features.

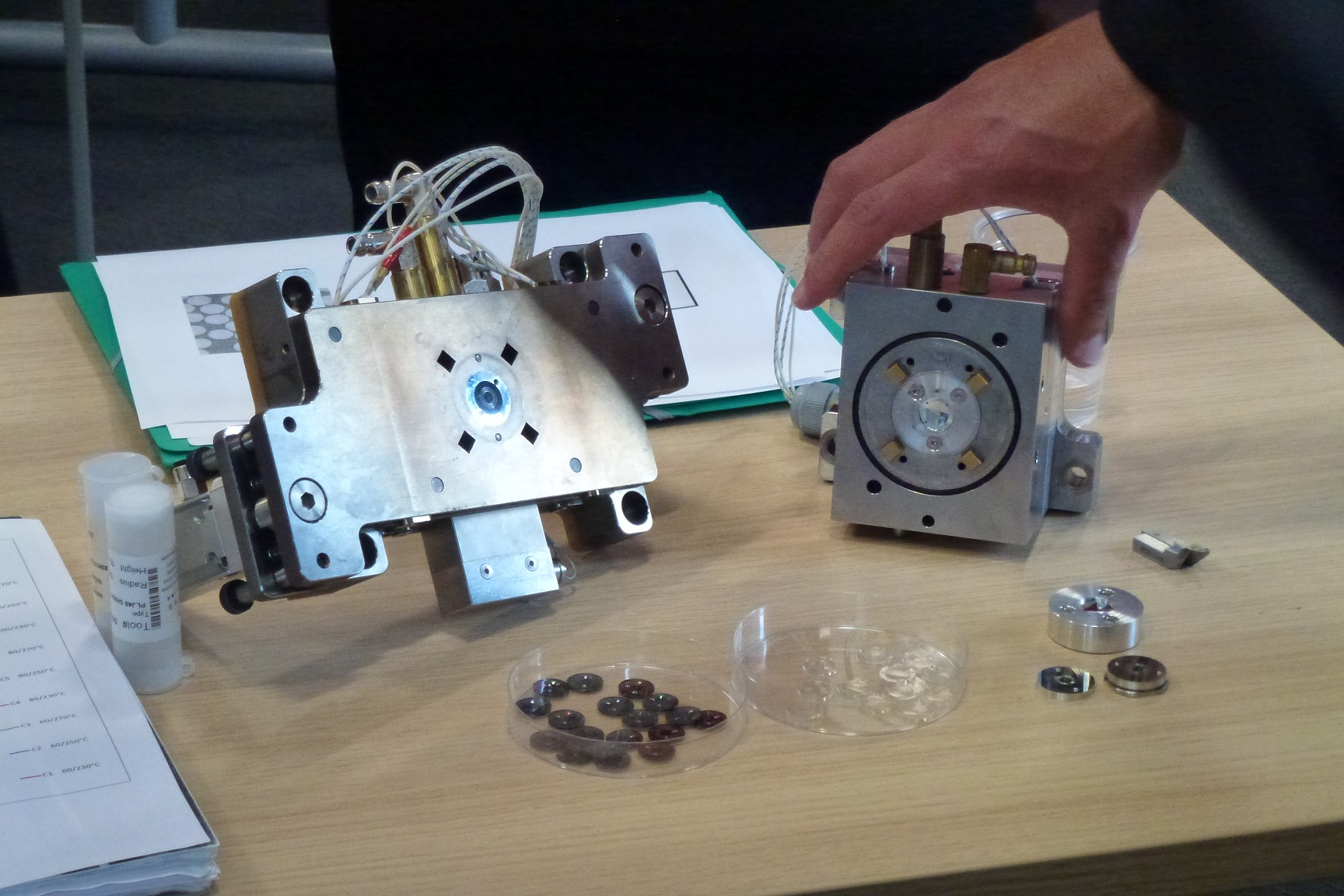

An insert mould assembly was designed and manufactured purposely for this project. The inserts were machined using a diamond turning ultra precision lathe. Micro features such as diffraction gratings were micro-injection moulded under different conditions. The replication quality of the gratings and surface roughness of the lens were measured since these are the most critical characteristics.

This research project was undertaken within the Cranfield University Precision Engineering Institute as part of an MSc research project supervised by Dr Paul Comley.