Project Researcher: Jon Parkins

High powered lasers have significant applications in manufacturing and spatial light modulators can improve tunability. Current commercially available technology cannot handle the high powers required. This project investigated current devices, in particular liquid crystal (LC) and micromirror devices.

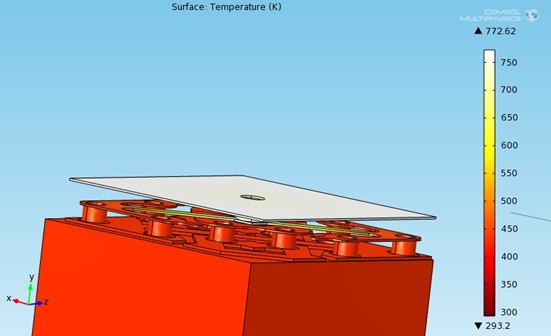

A finite-element model was built to simulate power handling capabilities of the devices. An LC device is predicted to handle a Gaussian beam of 8.33W with active cooling, clearly showing that LC devices are not a suitable technology for this application. Micromirror simulation predicted steering of a 550W Gaussian beam was possible with active cooling. Experimental testing featured a square top hat beam to illuminate the device and the temperature was measured using pyrometers. The non-cooled device showed significant visible melting damage after illumination with 150W of power from a fibre laser for 10s, with temperature measured approaching 480°C.

The model predicts 70W for this situation, with the discrepancy attributed to thermal diffusion into external device casing which was not considered in the model. Based on the findings, a new design and manufacturing route for an SLM were recommended to increase power handling performance.

Figure: Measurements made on commercial micromirror devices and the model based on them used to predict temperature profiles in a device pixel up until the material melting point.

This research was conducted during 2012-2013 as part of the first cohort of the MRes programme within the Centre for Doctoral Training in Ultra Precision at the University of Cambridge, supervised by Prof Bill O’Neill and Dr Martin Sparkes.

Contact Jon Parkins