An inkjet/ultrafast laser hybrid for digital fabrication of biomedical sensors – Ms Yoanna Shams

New digital technologies are needed to compliment lithography for low volume manufacturing of personalised biosensors and companion diagnostics. These new technologies will enable ultra-precise patterning of advanced functional materials that are often sensitive to the lithographic process, while also minimizing expensive biological and nanomaterial waste.

The focus of the PhD research is to develop a novel manufacturing method for high resolution digital patterning of functional materials for niche, low volume applications such as sensors and responsive devices. The underlying techniques include:

Inkjet Printing:

a. Biological elements,

b. Advanced functional materials for sensing

c. Catalysts for nanomaterial growth

Ultrafast Laser Ablation:

a. Accurate structuring of sensing elements to sub-micron resolution,

b. Controlling the surface chemistry and delivering quantitative sensing

The three key developments during the time frame from March to October 2015 are listed below:

i) A detailed literature review was conducted on the key technologies in biosensing and emerging technologies in nanofabrication and production of sub-micron scale biosensing platforms. This was part of the first year report and was also a separate deliverable for the industrial partner, MSolv Ltd.

ii) A first year report was submitted and examined.

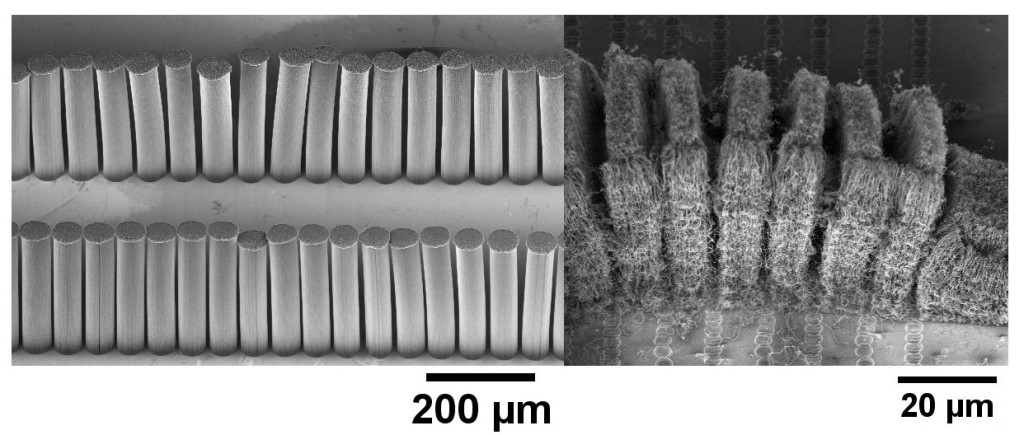

iii) Earlier work examined growing carbon nanotube forests from standard evaporated films of catalyst. Recent work has developed this for inkjet printed catalyst. Carbon nanotube forest growth was analysed with variations in ink concentration (and hence surface tension, viscosity) and droplet spacing. This shows a range of growth behaviours linked to the drying patterns and has been analysed with Raman spectroscopy, optical interferometry and electron microscopy.

iv) Leading on from earlier work ablating standard catalyst films, recent work examined ablation of the printed catalyst to pattern inkjet printed structures. This shows a sensitivity to laser power that shifts between improving growth in exposed areas and stopping growth completely, which needs to be followed up in later work. Biological molecules will also be targeted for the next stage of work, in place of the catalyst, to help with the fabrication of biosensors.

This research is supervised by Dr Ronan Daly, Institute for Manufacturing, University of Cambridge in collaboration with M-Solv Ltd and The Centre for Science Technology and Innovation Policy (CSTI).