Project Researcher: Cindy Potyrala

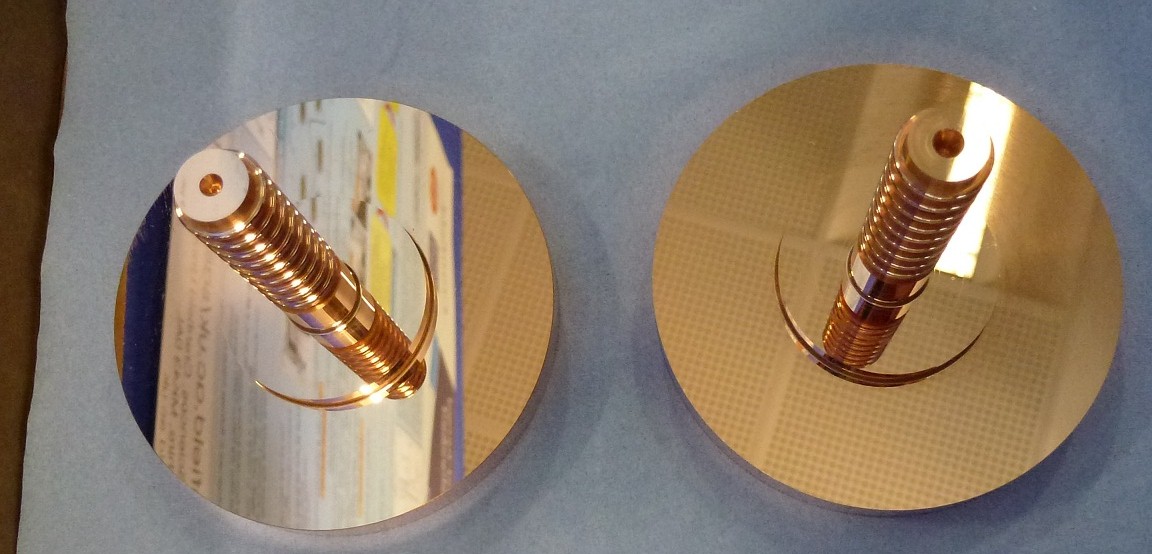

The surface finish of Compact Linear Collider (CLIC) copper discs and radio frequency (RF) requirements is essential as they undergo a diffusion bonding process. These discs can become marked and damaged easily. The achieved surface texture is highly affected by the diamond turning operation. These copper discs have sub-micron tolerances and nanometric surface roughness requirements.

A scratch study was carried out to define a maximum size of scratch that can be tolerated as the discs are subjected to an etching process. Measurements before and after etching of maximum height peak to valley (Pt), depth and width of the scratch were performed. All the parameters show a tendency to decrease after etching. The scratches with a Pt below of 1.5 µm before etching decrease up to 1 µm after the etching process.

Disc surfaces and the critical iris features were also diamond turned at different feed rates in order to analyse the influence on the surface finish and form accuracy. When the feed rate increases, the surface roughness average (Ra) increases. An optimum feed rate exists and test results will indicate this value.

This project was undertaken at Cranfield University as part of an MSc research project during academic year 2012-2013, sponsored by CERN and supervised by Prof Paul Shore.