Anode Materials for High Power Microwave Devices – Mr Daniel Gortat

Introduction

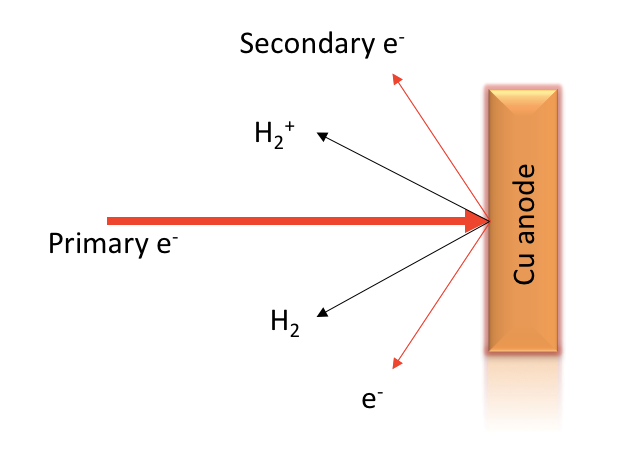

Recent advancements in diodes for High Power Microwave (HPM) devices are towards new materials for cathodes and anodes. While the investigations of cathodes appear to have reached a high level of success, the anode area still remains underdeveloped. Present anode materials limit the lowest achievable pressure in an HPM device, thus reducing its efficiency. The challenges lie with the anode’s significant contribution to outgassing and plasma formation, caused by its secondary electron emission – all of which are thermally driven phenomena generated by the electron beam impacting the anode’s surface.

The goal is to eliminate these products and thus increase the HPM’s efficiency by investigating materials which would most benefit anode applications, as well as finding optimal outgassing and secondary electron emission reduction methods and applying them to the selected material choices.

Experimental

Laser surface melting was used to reduce the outgassing of metal anodes. Stainless steel was treated with 1 kW CW CO2 and 20 W CW Yb Fibre lasers. The results showed a 50 % reduction in outgassing after treatments at high laser energy density. Additionally, surface roughness was reduced by 70 % for a single laser pass with 20 W CW Yb Fibre laser.

Ongoing Research

Materials:

- Metals – solids Stainless Steel/Copper/Nickel

- Graphene

- Highly Ordered Pyrolytic Graphite

Daniel’s PhD research is based at the Institute for Manufacturing, University of Cambridge under the supervision of Dr Martin Sparkes and Prof Bill O’Neill.

Outputs

Posters

Gortat, D. (2016). Anode materials for high power microwave devices, Poster presentation to the EPSRC Centre for Innovative Manufacturing in Ultra Precision Steering Meeting Committee, 24 February 2016, Cranfield University, UK.

Digital Media

Gortat, D. (2015). Anode Materials for High Power Microwave Devices. PhD project video produced for an informal Centre competition in 2015 where Daniel came first.