Project Researcher: Raham Jahromi

Depending on the growth conditions or preparation method used, thin films can be under tension or compression. If these values are too large they can affect both the lifetime of a device or its structure.

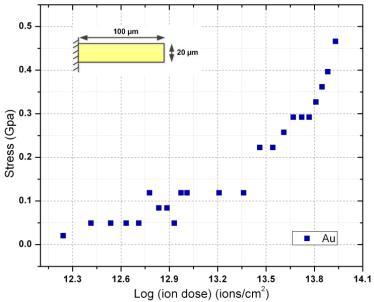

A technique based on focused-ion beam (FIB) system has been proposed. The advantage for such measurements is that it would be site specific and enable stress to be mapped on the sub-micron length scale. Unfortunately, as part of the FIB milling process Ga is implanted into the material being cut and damage can be created. A concern with this is that the implantation itself may affect the stress being measured and thus give erroneous values.

This project had two main aims: To investigate how much stress is induced into a range of materials by focused ion beam imaging and milling and to develop a method to measure the residual stress across a wafer; to investigate the first aim prefabricated cantilevers coated in different metals were used.

These were implanted with different Ga doses and the resultant deflections measured using secondary electron imaging. These experiments showed that for the films used, the stress induced during FIB imaging and milling exceeded the initial residual stress. This implies that FIB-based methods may have limited use. Also, the experimental results indicated that the stress induced may be dependent on the exposing and milling conditions themselves. If so it would be very difficult to differentiate between this stress and the original stress in the layers.

The second aim, to develop a technique that could map the stress across large areas such as wafers, could not be investigated fully since the membranes used kept breaking during FIB milling.

Figure: Graph of the change in stress (GPa) against dose (ions/cm2) for Au cantilever sample. The sample had a dimension of 100 x 20 x 0.5 microns. Initially, the cantilever had a stress of 0.284 Gpa.

This research was conducted as part of the first cohort of the MRes programme within the Centre for Doctoral Training in Ultra Precision at the University of Cambridge, supervised by Prof Bill O’Neill and sponsored by Carl Zeiss.