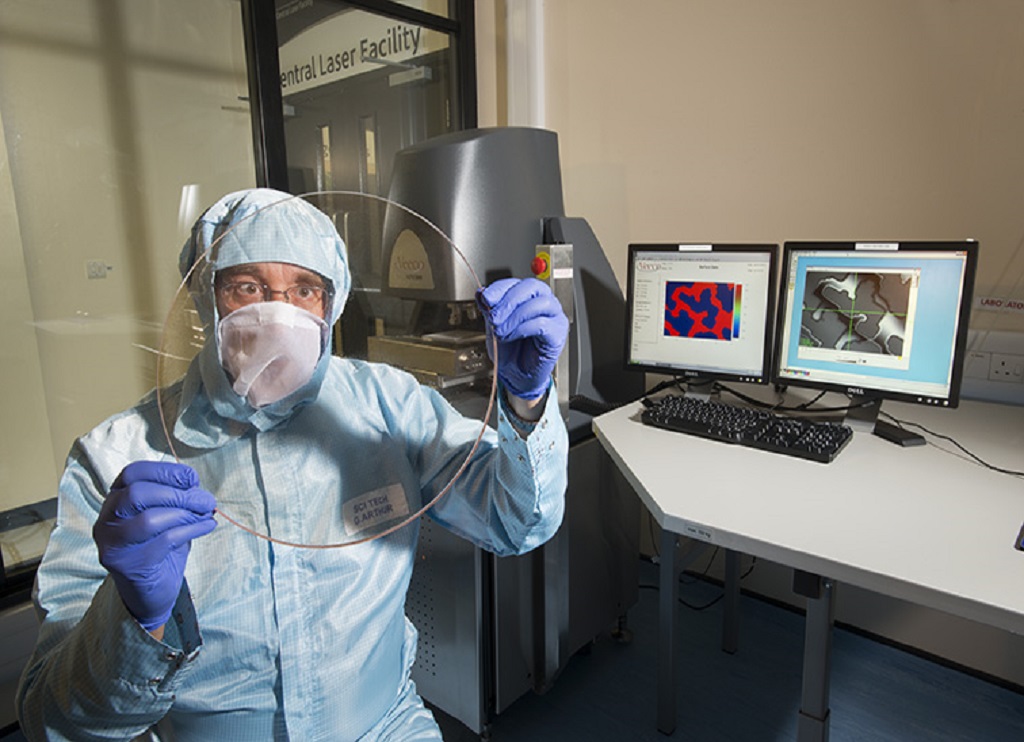

Scitech Precision Ltd. is a spin-out from the Science and Technology Facilities Council which combines expertise in micro-assembly and micro-engineering with extensive insight into the physics behind high power laser science. In addition, Scitech Precision provides a laser micromachining service using Excimer, 355nm and 1064nm lasers.

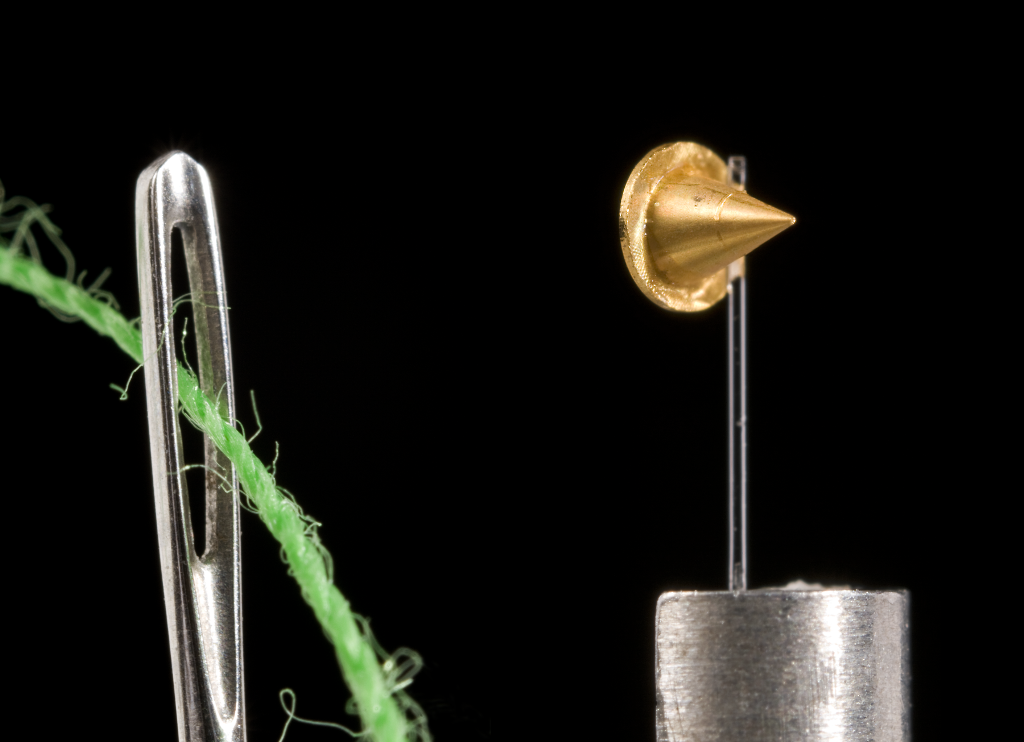

In order to consistently produce high quality laser micro targets Scitech draws on 40 years of experience gained in the production of tens of thousands of targets delivered to groups worldwide. We have become highly skilled in the production of a wide variety of highly complex, multi-material, target structures. All the targets we produce are characterised using high specification metrology tools in our dedicated clean rooms.

Cones, spheres, hohlraums, mass-limited targets and backlighter assemblies are a few examples of the more complex 3D components. MEMS-based fabrication processes are also used to create complex geometries in volume, with dimensions and tolerances not achievable by other methods. Foils can be produced as complex multi-layered, multi-material structures including embedded dots in metal or plastic.

We also produce equipment for high throughput laser experiments, we will work with you to develop the optimum mounting geometry for your experiment.

Scitech Precision offers a wide variety of laser processes including micromachining of an extensive range of materials. We have processed metals, ceramics, composites, PEEK, Carbon forms, Silicon and optical materials. We are also able to offer the laser cleaning of delicate components and the laser removal of layers as thin as a few nanometres from component surfaces.

We are uniquely placed to offer proof of concept and low volume manufacture solutions enabled by high speed scanners and stages: from the profiling of specialist flexible printed circuit boards to the machining of a 10 micron well in single crystal diamond or the manufacture of electrical probes much finer than a human hair. Lasers available include 193/248nm, 355nm, and 1064nm systems.

Phase plates are transparent optics which transform the shape and intensity profile of a focused laser beam, for example, into a circular or elliptical beam shape with a “top hat” intensity profile. Each phase plate is beam specific taking into account the laser wavelength and beam diameter along with the required focal length. The phase plates have a high damage threshold making them suitable for use with high power lasers. Anti-reflection coatings are applied to optics to reduce the loss of transmitted energy and to eliminate unwanted, potentially damaging, back-reflections. These coatings can be applied to phase plates as well as plain windows and lenses in the beam path and are produced in two forms: vacuum compatible Teflon-based technology and colloidal silica variants, suitable for atmospheric use.

Optics up to 300 mm in diameter, optical coatings suitable for wavelengths from 200 to 1900 nm.