SprayLaze is a metal coating technique which has being developed in order to allow the formation of metal deposits onto a variety of substrates. It has evolved from the Cold Spray process and aims to capitalise on the advantages of this method, while mitigating some of the limitations by removing the necessity for helium as a process gas.

View a video here of the supersonic laser deposition.

Project aims

- To develop a system for the deposition of metal and composite coatings by laser assisted deposition.

- To demonstrate the ability to deposit coatings using nitrogen as the accelerating gas for a wide range of powder/substrate material combinations.

- To establish the process parameters required for successful deposition of a variety of materials.

- To develop the capability to deposit industrially relevant coatings.

- To pursue collaborative partnerships in order to benchmark the process against current deposition technologies.

- To establish that coatings meet industrial requirements through chemical, mechanical and microstructural characterisation.

The process

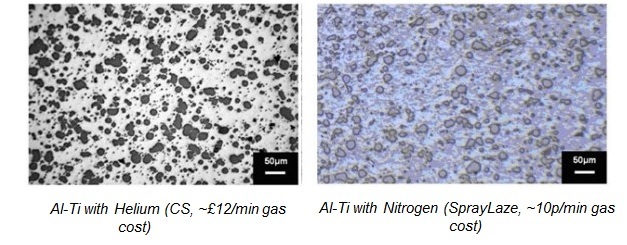

SprayLaze has been engineered in order to widen the range of materials which can be deposited using nitrogen, dramatically reducing process costs and increasing the range of applications for which Cold Spray (CS) may prove attractive.

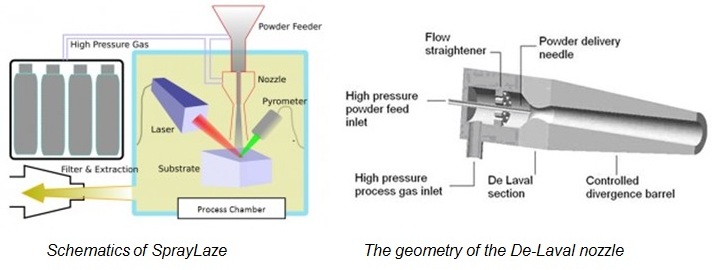

In this process, powder is accelerated in a supersonic gas jet before it impacts the substrate. A laser heats the deposition site to between 30 and 80% of particle melting point. This significantly reduces particle strength so that, on impact the particles undergo significant plastic deformation which leads to localized heating and flash welding at the interface. The use of a laser allows impact velocities around half those used in CS. Reducing the required velocity allows nitrogen to be used as the process, gas reducing expenditure from £12 per minute for helium to approximately 10 pence per minute. This reduction in operating costs means that SprayLaze may be suitable for many applications for which CS has proved too costly, allowing the fully solid process route found in Cold Spray to find a use in a broad range of applications.

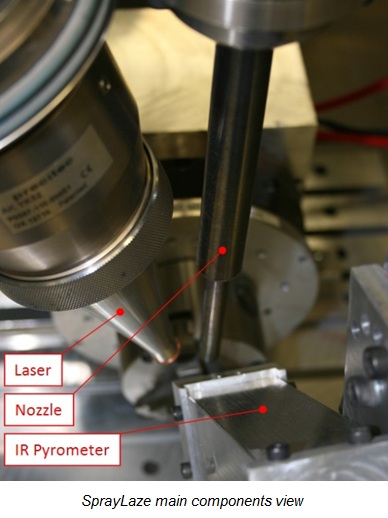

The SprayLaze system

The SprayLaze system consists of a high pressure (10-30 bar) nitrogen gas supply which is split and sent to a converging-diverging (De-Laval) nozzle both directly and via a high pressure powder feeder, where metal powder particles are entrained within it. The two streams recombine and pass through the nozzle where they are accelerated to supersonic speeds. The high-velocity, powder-laden gas jet exits the nozzle and is directed towards a substrate. The powder stream impacts a region of the substrate which is simultaneously illuminated by a laser (current maximum power is 4kW). The Laser power is controlled by a closed loop feedback system (PID) which uses an infra-red pyrometer to monitor the deposition zone temperature in real time.

Coatings

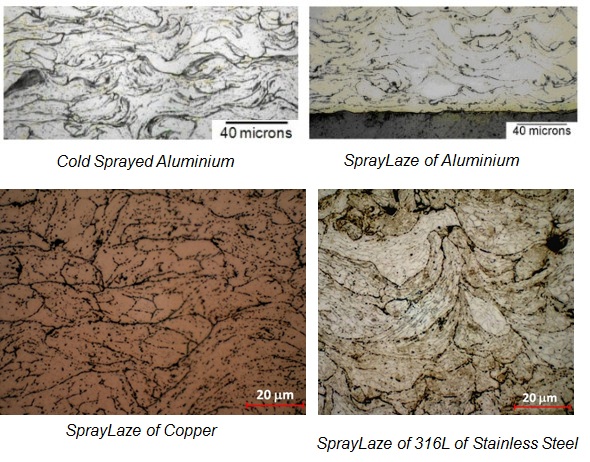

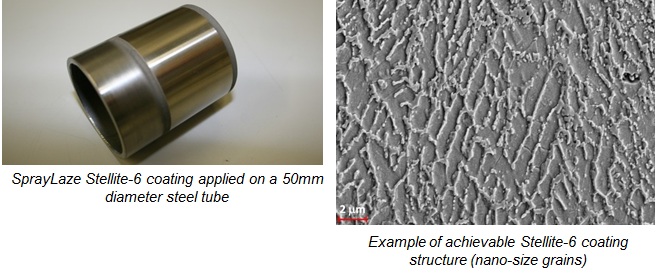

Coatings have been deposited using Aluminium, Copper, 316L stainless steel, Al-Ti mixed powder, Titanium, Ti64, Stellite-6, WC-Co and others. Conventional deposition technologies involve melting the powder and therefore must be carried out in controlled atmospheres to avoid problems with oxidation, in contrast with SprayLaze. Coatings produced so far compare well against CS and Laser Cladded counterparts, with similar or superior structures being deposited at lower costs and higher processing speeds.

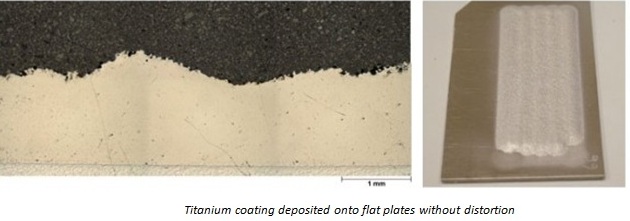

Dense, low-oxide content titanium coatings have been deposited using particle velocities below their critical threshold.

Chemically etched cross-sections show the coating structure in SprayLaze is similar to CS where spherical particles have undergone a large degree of deformation on impact upon the substrate.

Hard-facing of engineering components with the formation of Stellite-6 coatings. The analysis of the deposits had shown a grain structure not larger than few hundreds of nanometres giving the potential for an excellent wear performance. It was demonstrated the properties of the feedstock are maintained during the process.

Coatings can be deposited under conditions which results in significantly lower gas and operating costs against helium CS, whilst maintaining similar final properties.

Advantages

- Higher coating quality and performance against CS, HVOF, Plasma Spray and Laser Cladding.

- The deposition of dense or porous coating is achievable.

- High bond strength.

- Fast process, low cost.

- 100% controllable.

Applications

- Titanium coatings for aerospace and biomedical components.

- Hard-facing for the tool manufacturing industry.

- Repair of engineering components.

- Corrosion protection layers.

- Metallization of non-metallic surfaces.

This research funded by EPSRC and the UPS2 IKC was undertaken in collaboration with IPG Photonics.

Contact Professor Bill O’Neill Contact Dr Martin Sparkes Contact Dr Rocco Lupoi Contact Dr Andrew Cockburn